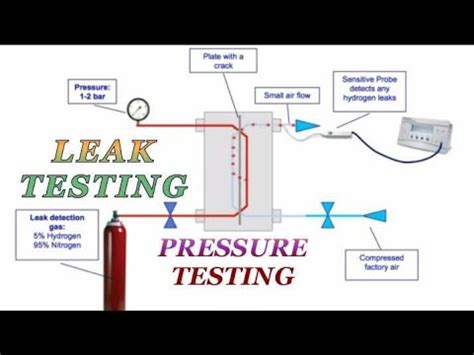

Positive pressure Leak Tester distribution|system pressure testing for leaks : retailer Protecting Water Quality Through Distribution System Pressure Management Pressure management involves maintaining pressure within an optimal range throughout a distribution system, which may have varying topography and water demand. Effective pressure management can help sustain high water quality, reduce main breaks and

Resultado da 22 de ago. de 2023 · 9.5K curtidas,29 comentários.Vídeo do TikTok de KevinMariele Conta Secundária (@kevinmariele.oficiall): "Mano???? .

{plog:ftitle_list}

Faça suas apostas em futebol na Sportingbet. Aproveite as melhores odds e os melhores mercados em partidas do futebol nacional e do futebol internacional.

Step 4a — Typical Positive Pressure Testing: Connect one end of the orifice tube to the duct system using a short piece of single-wall flexible duct. The arrow on the calibration sticker shows direction of flow. Step 4b — Typical Negative Pressure Testing: For all standard components .

unraid test hard drive

• A minimum of 10 Pascal positive differential air pressure should be maintained • Should seek a 6-log reduction of BI for isolator decontamination • The resistance of the BI to .Pressure Decay Leak Testing This is a common type of leak test in which you pressurize the part or system under test and measure the rate of pressure loss over time, correlated to a .Positive and negative duct testing in one rig Portable Automatically calculates leakage rate in real-time. Products search. . EUROVENT 2/2 Air Leakage Rate in Sheet Metal Air Distribution Systems; . Duct Leak Tester (+/-) with no .

The 6D Laskin-Nozzle aerosol generator is a small, light yet rugged portable, self-contained generator. It is ideal for testing a wide variety of filter systems with airflows up to 2,000 cfm by generating a polydispersed, submicron aerosol. .Protecting Water Quality Through Distribution System Pressure Management Pressure management involves maintaining pressure within an optimal range throughout a distribution system, which may have varying topography and water demand. Effective pressure management can help sustain high water quality, reduce main breaks andAir leak testing is a common method used for leak testing. It is a flexible test method that can be used to leak test a wide variety of parts and applications. Under the umbrella of air leak testing are several specific methods. In this ebook, we’ll cover the following types of air leak testing: > Pressure Change Method A

Step 5 — For positive pressure tests (5a), the fan discharge should be con-nected to the orifice tube. For negative pressure testing (5b), the fan intake will be connected. With McGill AirFlow’s 4-inch Leak Detective test components, the fan comes equipped with a tapered nozzle, which can connect to either

• Insert positive pressure source with monitor into test sample • Submerge test sample in water; apply air to target pressure; hold for pre-determined time • Observe for continuous stream of bubbles. Test (External Vacuum): ASTM D3078 • Submerge test sample in water or other suitable fluid in vacuum chamber

The cuff leak test is used to predict risk of post-extubation stridor in intubated patients. Use and interpretation of the test needs to take into account the overall context of the patient's condition and the management implications . Positive End Expiratory Pressure (PEEP), Pulmonary Mechanics, Pressure Vs Time Graph, Pressure vs Volume .

Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see specifications that may require return air or exhaust systems to be leak tested under a vacuum (negative pressure). To perform a proper duct leakage test under negative pressure using an ORIFLOW duct leakage tester, perform .Testing Capabilities. We ensure each assembly is leak-free through 100% testing. We test assemblies multiple ways: Bubble Leak Detection – Film Solution: A positive pressure is applied to the assembly. The pressure applied can be as high as 1000 PSIG, or higher upon request. Swagelok Snoop is applied to the potential leak points and then .Quiz yourself with questions and answers for Water distribution practice test D1 /D2, so you can be ready for test day. . If possible why should a main water leak be repaired under pressure. What are the names of positive displacement pumps. 14 of 61. . The bubbles formed in a positive multiple tube fermentation test are.

Model: Internal Chamber. Dimensions (mm) Specification: BLT-P400: 420(L) x 320(W) x 300(H) ASTM F2096 – Bubble Leak Tank to test the integrity of sealed packs using a positive pressure via a needle/tube inserted in a pack. Pressure (Mechanical) Leak (Quality Verification) x: x: . (Positive Sequence), Load Loss. . and potential problems associated with attempting to establish absolute values to apply across the board for this test on distribution class transformers (See Notes 1, 2 & 3 of Table 4, IEEE C57.12.90-2021, p. 67). .

leak test instrument for industrial quality controlafter 46 years, and 250,000 testers installed in more than 5,000 customers worldwide, ateq presents its revolutionnary leak tester range : the f6 series including a compact leak tester f620, a weatherproof leak tester f610 and the f670 in its 19″3u industrial format.Dry air leakage rate measured at 1 atm differential pressure across an orifice leak (i.e., leak inlet pressure of 1 atm versus outlet pressure of approximately 1 Torr) at 25 . The theoretical correlations of orifice sizes to air leakage rates were provided by Lenox Laser, Glen Arm, MD. Leakage rates are approximation ranges. Leak testing is a Non-destructive Testing method or process where inspectors apply pressure to an object to locate defects that are causing leaks. . or other type of flaw, the liquid or gas it is holding can leak out. This .• CCI testing principles • Leak and Positive controls • Gas flow: flow rate & leak size • Correlation between leak size (flow rate) and microbial contamination risk . A Dry air leakage rate measured at 1 atm differential pressure across an orifice leak (i.e., leak inlet pressure of 1 atm versus outlet pressure of approximately 1 Torr .

1.1 This practice describes a method for determining the leakage rate of a vessel subject to a positive pressure difference. The technique is based upon evaluation of the change of mass within the test object based on a pressure decay measurement. The pressure decay measurement uses the ideal gas equation of state and the measured pressures, temperatures, .

DEZEGA recommends using the UPG leak tester to test regularly for leak tightness on waist-worn self-contained self-rescuers. . The user manual describes the construction and requirements for everyday use of the positive pressure leak testing device UPG for self-contained self-rescuers. Languages: EN, RU, TR, UK, ES. as-upg-124 .

system pressure testing for leaks

Another option is to use the positive-pressure leak test. A test gas is used to fill the apparatus being inspected and to build up a slight positive pressure; the test . Positive pressure testing is, on the other hand, a technique commonly employed in tank engineering. When dealing with large containers and the long test periods they require .for testing. 5. Significance and Use 5.1 Leaks in blister packs may affect product quality and such defects can arise from imperfections in the packaging material or bond between the sealed surfaces. 5.2 This method of leak testing is a useful tool as it allows non-destructive and non-subjective leak testing of blister packs.The BLT bubble leak tester uses regulated pressure to test the integrity of sealed packs. Convenient, easy and quick to test single or multiple packs. . Also available is the BLT-P range which tests the integrity of sealed pack using a positive pressure via a needle / tube inserted in a pack. This alternative model meets standard ASTM F2096. .

Performing a Positive Pressure Test to Search for Leaks Last updated Dec 22, 2020 Discover the effectiveness of pressure decay testing as a method for leak detection in this informative article. Explore the principles behind this technique, its applications in various industries, and the benefits it offers in terms of accuracy and efficiency. Gain insights into the process, equipment requirements, and best practices for conducting pressure decay tests, .Positive pressure is a pressure within a system that is greater than the environment that surrounds that system. Consequently, if there is any leak from the positively pressured system, it will egress into the surrounding environment. This is in contrast to a negative pressure room, where air is sucked in. [1] [2] Pressure decay leak testing uses a pressure loss measurement to identify a specific leak rate, making it one of the most effective means of testing for leaks in virtually any type of part. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. You can conduct pressure decay testing using either air .

Positive pressure isolator for aseptic preparation, compounding & dispensing of non-hazardous drugs (TPN / CIVAS) in hospital pharmacies. . User friendly automatic pressure decay leak test Two-glove and four-glove models available in rigid coated stainless steel or flexible PVC; . Unit B11 Broadlands, Heywood Distribution Park, Heywood .

Positive Pressure Test: Get Positive TMP (0:02 – 0:05): in this step the fresh valves are energized and loading pressure is used to push thru them to generate positive pressure at the Dp transducer. A pressure of at least +350 is achieved, then the pressure is reduced to +250. (Mainly watching “dead time” – a leak will cause no pressure .

positive gas leak testing

6.8. HD. Amid a future war between the human race and the forces of artificial intelligence, a hardened ex-special forces agent grieving the disappearance of his wife, is recruited to .

Positive pressure Leak Tester distribution|system pressure testing for leaks